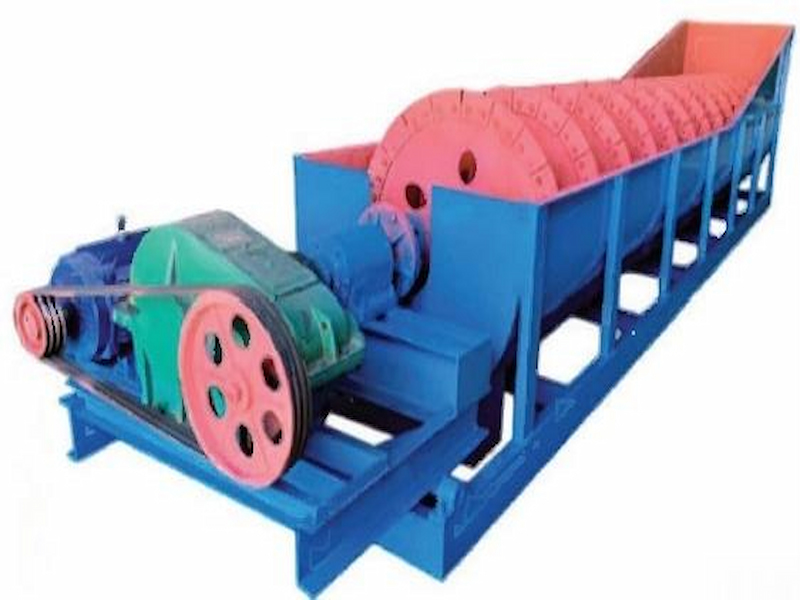

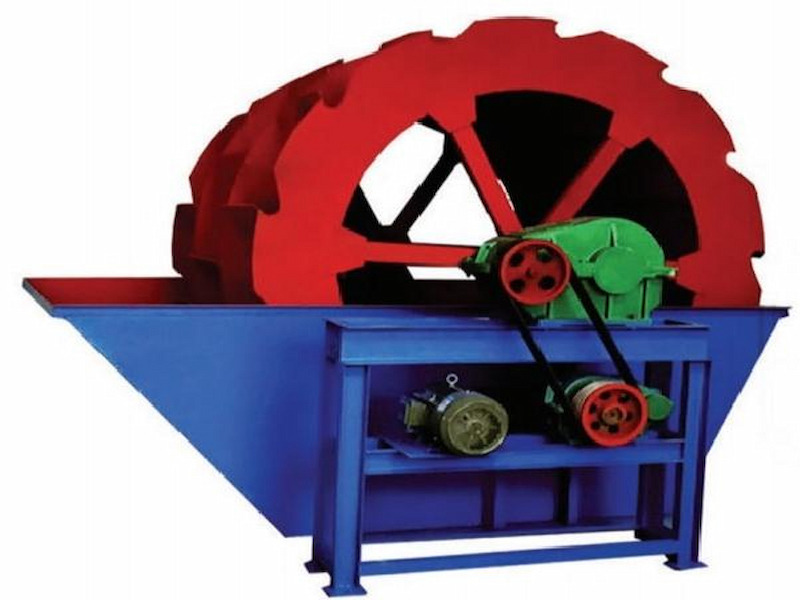

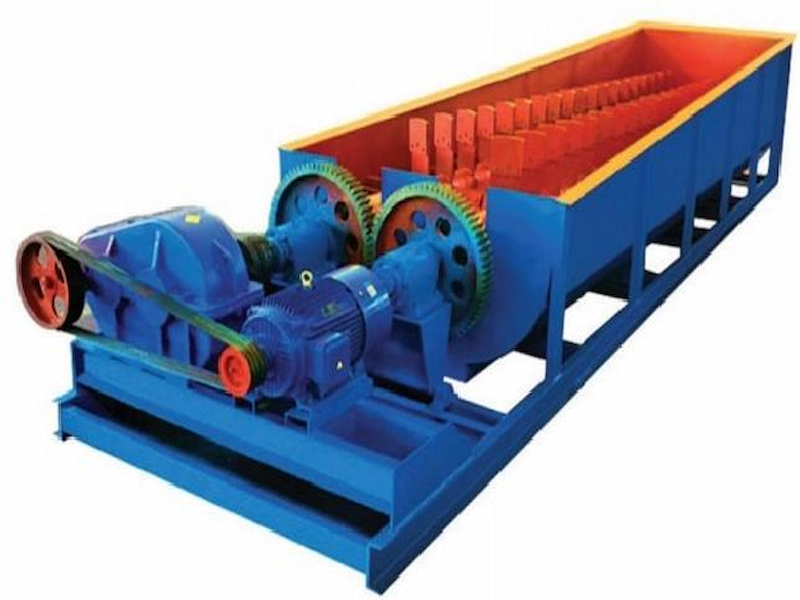

CATHAY spiral sand washing machine is specially designed for cleaning sand and gravel aggregates and mine tailings. It uses double spiral strong rolling technology to achieve efficient cleaning. The mud content of finished sand is ≤0.8% (national standard ≤3%), the fine sand recovery rate is ≥95%, and the single machine processing capacity is 50-500 tons/hour.

Core advantages

✅ 99% cleaning rate

- Extended spiral trough (≥6 meters), mud and sand are fully separated

- Adjustable inclination design (15°-25°), adaptable to different mud contents

✅ Zero loss of fine sand

- Optional cyclone + dewatering screen recovery system

- Recovery rate of fine sand above 0.075mm ≥95%

✅ Water-saving and durable

- Water consumption is only 1.8m³/ton of sand (3-5m³ for traditional equipment)

- Blade lining wear-resistant alloy steel, life of 20,000 hours

✅ Intelligent operation and maintenance

- Automatic protection against current overload

- Bearing seals to prevent sand, free replacement for 3 years

Technical parameters (LX-1500 standard model)

| Parameters | Indicators |

|---------------|-------------------|

| Processing capacity | 150t/h |

| Spiral diameter | Φ1500mm |

| Power | 15kW |

| Water consumption | 270m³/h |

| Cleaning rate | ≥99% |

| Fine sand recovery rate | ≥95% (with recovery system) |

Compared with traditional equipment

| Indicators | CATHAY screw machine | Ordinary sand washing machine |

|---------------|-------------|-----------|

| Mud content | ≤0.8% | 2%-3% |

| Water consumption per ton of sand | 1.8m³ | 4m³ |

| Maintenance cycle | 500 hours | 200 hours |

Applicable scenarios

✔ Sand and gravel aggregate washing and mud removal ✔ River sand mining and purification

✔ Iron ore tailings recovery ✔ Construction waste recycling

Table parameters

|

型号 Model

|

螺旋直径 螺旋转速

Diameter(mm)Speed(r/min)

|

水槽Wat 长(mm)

|

er channe 宽(mm)

|

倾斜角( · )

Angle of roll

|

洗砂量(t/h) Sand return

|

功率(kw)

Power

|

重量(kg) Weight

|

|

FLG-3

|

300

|

20~40

|

3500

|

390

|

14°~18”30'

|

1~5

|

1.5

|

1100

|

|

FLG-5

|

500

|

15~30

|

4500

|

555

|

14°~18°30'

|

5~10

|

2.2

|

1600

|

|

FLG-7

|

750

|

15~30

|

5500

|

830

|

14°~18°30'

|

10~25

|

3

|

2900

|

|

FLG-10

|

1000

|

15~28

|

6500

|

1112

|

14°~18°30'

|

25~50

|

5.5

|

4400

|

|

FLG-12

|

1200

|

12~25

|

6500

|

1372

|

14°~18°30'

|

50~70

|

7.5

|

8800

|

|

FLG-15

|

1500

|

12~20

|

8265

|

1664

|

14°~18°30'

|

70~120

|

11

|

11680

|

|

FLG-20

|

2000

|

10~20

|

8400

|

2200

|

14°~18°30'

|

120~220

|

15

|

20450

|

|

FLG-24

|

2400

|

10~20

|

9130

|

2600

|

14°~18°30'

|

220~300

|

18.5

|

25650

|

|

FLG-30

|

3000

|

10~20

|

12500

|

3200

|

14°~18°30'

|

300~500

|

22

|

37000

|

|

2FLG-12

|

600×2

|

12~25

|

6500

|

1372

|

14°~18°30'

|

50~90

|

11

|

7800

|

|

2FLG-15

|

750×2

|

12~20

|

8250

|

1664

|

14°~18°30'

|

90~130

|

15

|

9680

|

|

2FLG-20

|

1000×2

|

10~20

|

8400

|

2200

|

14°~18°30'

|

130~240

|

22

|

15450

|

|

2FLG-24

|

1200×2

|

10~20

|

9130

|

2600

|

14°~18°30'

|

240~320

|

30

|

17650

|

|

2FLG-30

|

1500×2

|

10~20

|

12500

|

3200

|

14°~18°30'

|

320~600

|

45

|

29000

|