Product Overview

CATHAY sand screening machine is an innovative equipment integrating screening, washing, dehydration and fine sand recovery, specially designed for processing machine-made sand, river sand and sea sand. Through modular integrated design, a single device can complete the workflow of three traditional devices, reducing site occupancy by 60% and investment costs by 45%.

Core advantages

1. Four-in-one system

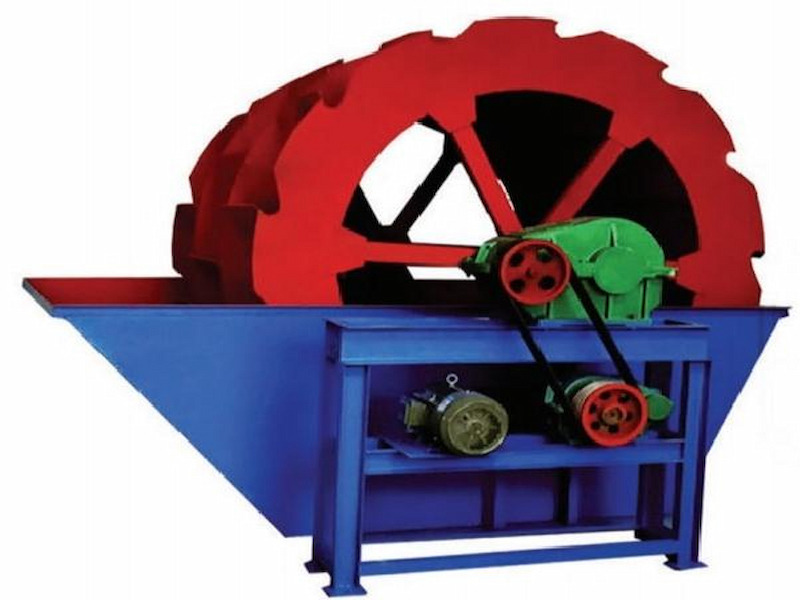

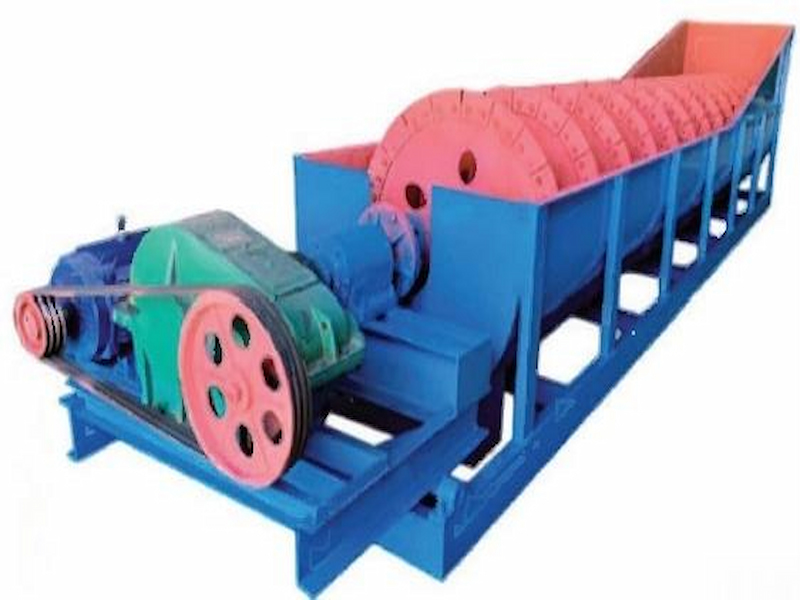

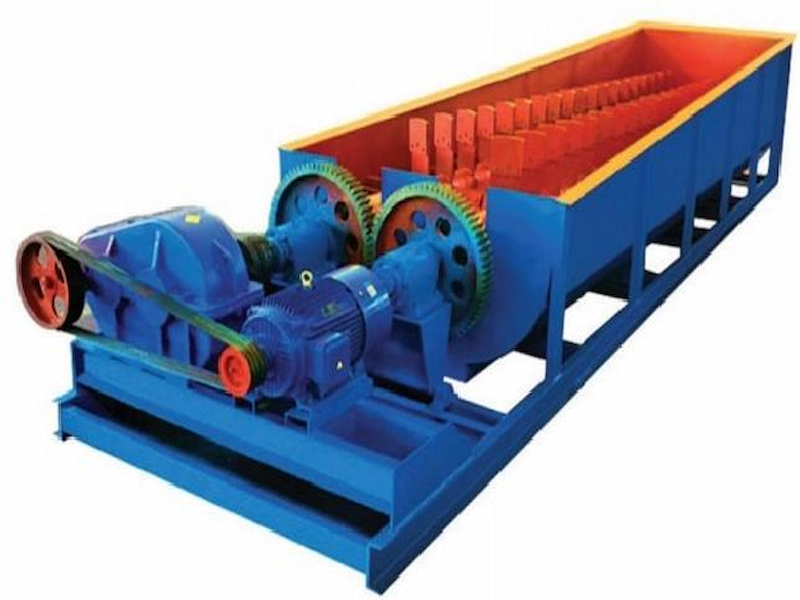

- Grading and screening: multi-layer vibrating screen (2-4 layers), grading accuracy 0.075-20mm

- Powerful water washing: double spiral grinding wheel, processing capacity **50-300t/h

- High-efficiency dehydration: high-frequency dehydration screen, finished sand moisture content <8%

- Fine sand recovery: cyclone + dehydration screen combination, recovery rate ≥95%

2. Energy-saving and environmentally friendly design

- Water circulation system: water consumption is reduced by 70% (only 1-1.5m³ water/ton sand)

- Zero pollution discharge: equipped with sludge filter press (optional)

- Noise reduction structure: overall noise ≤75dB

3. Intelligent control system

- PLC centralized control: one-button start and stop of all modules

- Fault self-check: real-time monitoring of bearing temperature, water pressure and other parameters

- Production statistics: automatic recording of shift production/daily production data

4. Durable structure

- Wear-resistant material: The screen plate is made of NM400 wear-resistant steel, with a service life of ≥18 months

- Anti-blocking design: Screen self-cleaning device

- Module quick change: Key component replacement time <2 hours

Technical parameters

| Module | Parameter details |

| Screening system | Vibration motor power: 2×7.5kW |

| | Screen surface size: 1800×4800mm |

| Sand washing system | Spiral diameter: Φ1500mm |

| | Processing capacity: 100t/h |

| Dewatering system | Dewatering screen area: 2.5m² |

| | Finished sand moisture content: ≤8% |

| Recovery system | Cyclone specifications: Φ350mm |

| | Fine sand recovery rate: ≥95% |

Compared with traditional solutions

| Indicators | CATHAY integrated machine | Traditional production line |

| Floor area | 200㎡ | 500㎡ |

| Installed power | 110kW | 180kW |

| Operators | 1-2 people | 4-5 people |

| Construction period | 3 days | 15 days |

Application scenarios

✔ Sand and gravel plant: cleaning and grading of machine-made sand aggregates

✔ Sand mining site: desludging and removing river sand/sea sand

✔ Construction waste: cleaning and recycling of recycled aggregates

✔ Mine tailings: resource utilization of fine particles

Company Project

|

型号 Model

|

生产能力(mm) Capacity

|

料斗尺寸(mm) Hopper size

|

筛网尺寸(mm) Screen size

|

输送带(mm) Conveyor belt

|

筛砂机功率(kw)

Power

|

输送机功率(kw)

Power

|

重量(t) Weight

|

|

20型

|

20-30

|

2000×1000

|

600×1500

|

500×4000

|

1.5

|

2.2

|

1.5

|

|

30型

|

30-50

|

2500×1000

|

800×2000

|

600×6000

|

2.2

|

3

|

1.9

|

|

50型

|

50-80

|

3000×1500

|

1000×3000

|

800×8000

|

3

|

4

|

2.5

|

|

75型

|

60-100

|

3000×2000

|

1200×3000

|

1000×8000

|

5.5

|

5.5

|

3.9

|

|

100型

|

80-150

|

3500×2000

|

1500×3000

|

1000×9000

|

7.5

|

7.5

|

4.8

|

|

120型

|

100-200

|

3500×2500

|

1800×4000

|

1200×10000

|

11

|

11

|

6.2

|