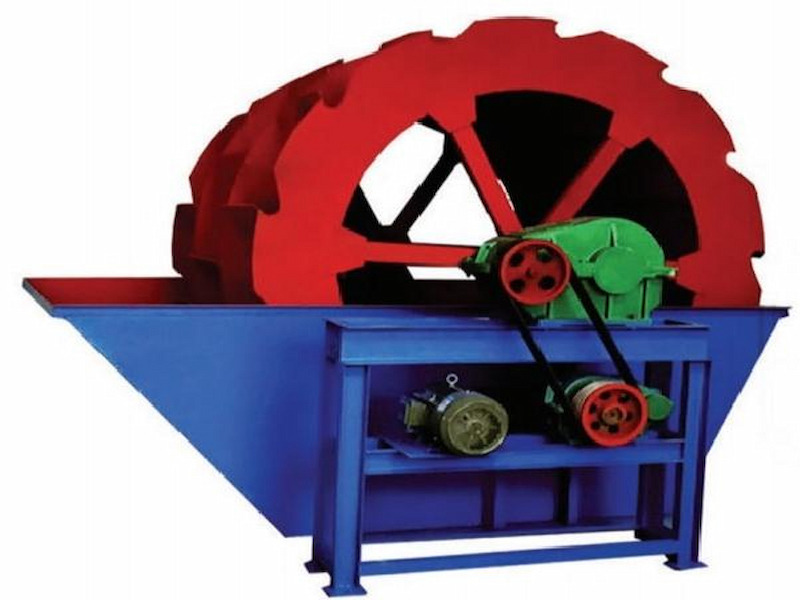

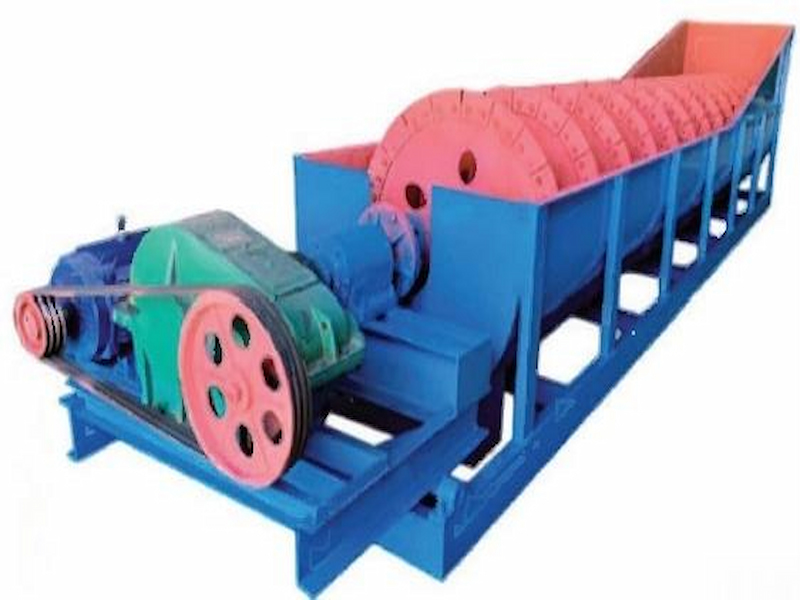

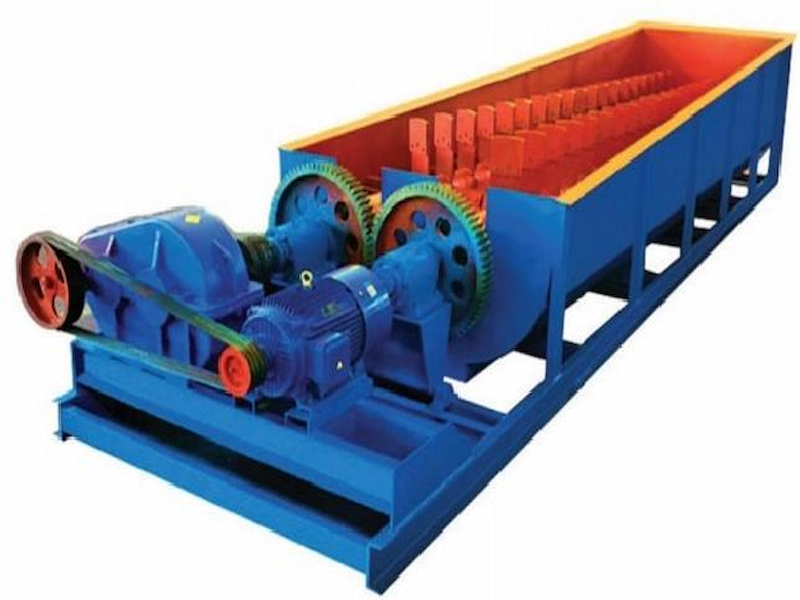

Product Introduction

CATHAY cylindrical ore washer is specially designed for high-clay and easy-to-cement ores, integrating strong scrubbing and grading screening. The clay on the surface of the mineral is peeled off by the high-speed rotating lining plate, and the ore grading is completed simultaneously. The cleaning rate is ≥98%, and the processing capacity is 50-500 tons/hour, which solves the problems of low efficiency and high water consumption of traditional processes.

Core advantages

✅ Scrubbing and screening synchronously

- Strong stirring of wear-resistant lifting plate in the barrel, clay stripping rate ≥95%

- End grading screen (5-80mm adjustable), coarse material is discharged directly

✅ Wear-resistant and long life

- Lined with high chromium alloy/rubber composite plate (hardness HRC60)

- Continuous operation for 60,000 hours without major repairs

✅ Energy saving and water saving

- Water consumption is only 2.5m³/ton of ore (traditional equipment 5-8m³)

- Frequency conversion drive saves 25% of electricity

✅ Intelligent anti-blocking

- Overload automatic reversal + high-pressure spray system

- Triple bearing seal to prevent mud and sand intrusion

Technical parameters (TS-3200 standard model)

| Parameters | Index |

| Barrel size | Φ3.2×6m |

| Processing capacity | 150-250t/h |

| Motor power | 75kW |

| Maximum feed size | ≤300mm |

| Cleaning rate | ≥98% |

| Water consumption | 375-625m³/h |

Comparison with traditional equipment

| Indicators | CATHAY drum machine | Trough ore washer |

| Clay processing capacity | ≤45% | ≤40% |

| Water consumption per ton of ore | 2.5m³ | 3.5m³ |

| Floor space | Reduced by 50% | - |

Applicable scenarios

✔ Cemented ore: Clay group crushing of manganese ore/nickel ore

✔ Placer gold ore: Gravel screening + gold particle recovery synchronization

✔ Construction aggregate: Deep mud removal of weathered mountain sand

✔ Iron ore: Red mud stripping on the surface of hematite

Table parameters

Table parameters

|

型号 Model

|

筛网大小(mm) Screen size

|

给料粒度(mm) Granularity

|

水压(mpa) Water gage

|

处理能力(t/h) Capacity

|

旋转速度(r/min) Velocity

|

功率(kw)

Power

|

重量(kg) Weight

|

|

RXT1030

|

≥5

|

≤100

|

0.4-0.5

|

30-50

|

25-28

|

15

|

4800

|

|

RXT1230

|

≥5

|

≤100

|

0.4-0.5

|

50-70

|

23-25

|

18.5

|

5800

|

|

RXT1545

|

≥5

|

≤150

|

0.4-0.5

|

70-120

|

18-22

|

30

|

6900

|

|

RXT1560

|

≥5

|

≤150

|

0.4-0.5

|

80-130

|

18-22

|

37

|

8300

|

|

RXT1845

|

≥5

|

≤170

|

0.4-0.5

|

90-130

|

20-21

|

45

|

11800

|

|

RXT1860

|

≥5

|

≤170

|

0.4-0.5

|

100-140

|

20-21

|

45

|

12800

|

|

RXT2060

|

≥5

|

≤210

|

0.4-0.5

|

120-160

|

19-20

|

55

|

14800

|

|

RXT2265

|

≥5

|

≤230

|

0.4-0.5

|

160-180

|

19-20

|

55

|

16500

|