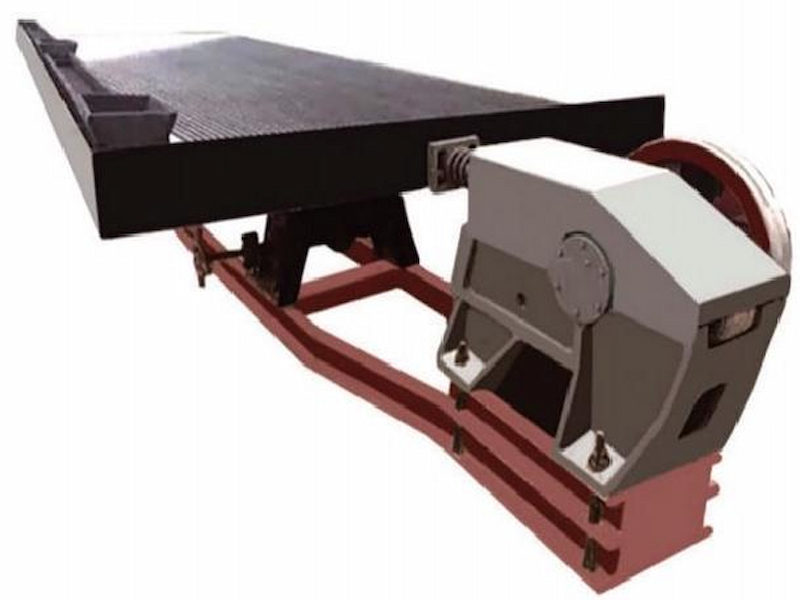

CATHAY Yunnan Tin Shaker: Professional-grade equipment for tin ore sorting

1. Targeted design, in line with the characteristics of tin ore sorting

CATHAY Yunnan Tin Shaker is specially developed for tin ore sorting. Its core parameters such as bed slope and stroke frequency have been optimized through long-term tin ore sorting practice. The bed adopts a special groove design. The groove depth and spacing are precisely set according to the sedimentation characteristics of tin ore particles. It can effectively slow down the movement speed of tin ore particles on the bed, provide sufficient time for the stratified sorting of tin ores of different particle sizes (0.04-2mm), and greatly reduce the loss rate of fine-grained tin ores. The enrichment ratio of tin ore for a single device can reach 30-50 times.

2. Fine stratification, high tin ore recovery rate and purity

Driven by asymmetric reciprocating motion, the bed produces longitudinal and transverse composite water flows. Due to the high density of tin ore particles, under the combined action of gravity, water flow thrust and bed friction, they slowly move horizontally along the bed surface and settle into the grooves at the bottom of the bed surface, forming a concentrate belt; the gangue minerals move quickly to the tailings area with the upper water flow, and the separation boundary is clear. The recovery rate of alluvial tin ore can reach more than 85%, and the tin grade of the concentrate after vein tin ore separation can be increased to more than 40%, far exceeding the separation effect of ordinary shaking tables.

3. Adapt to multiple types of tin ores and apply to a wide range of scenarios

CATHAY Yunnan Tin Shaking Table can not only efficiently process alluvial tin ore and vein tin ore, but also recycle the middlings and tailings produced during the tin ore beneficiation process to improve resource utilization. It can play a stable role in different process links such as rough selection, fine selection and scavenging selection of tin ore. It is widely used in small and medium-sized beneficiation plants in the main tin ore producing areas such as Yunnan, Guangxi and Hunan, as well as the raw material purification link of tin smelting enterprises. It is a classic equipment in the field of tin ore processing.

4. Stable structure and durable bed surface

The bed surface is made of highly wear-resistant cast iron, and the surface is specially quenched with a hardness of more than HRC50. It can withstand long-term friction and impact of tin ore particles, and its service life is 2-3 times longer than that of ordinary steel bed surfaces. The frame is welded with high-strength angle steel, with good overall rigidity. It is not easy to deform during high-frequency reciprocating motion, ensuring the stability of the bed surface movement trajectory and the consistency of the sorting effect, highlighting the strict control of the quality of the CATHAY brand.

5. Flexible operation and easy parameter adjustment

Equipped with a manual adjustment device, the bed surface slope (1°-5°), stroke (6-20mm) and stroke frequency (250-400 times/minute) can be flexibly adjusted according to the particle size and grade of the tin ore. The operator can judge the sorting status and make targeted adjustments by observing the position and width of the concentrate belt on the bed surface. No complex training is required. Ordinary workers can operate proficiently after short-term guidance, reducing the difficulty of production management and reflecting the humanized design of CATHAY equipment.

6. Low energy consumption and economical operating cost

The driving motor power is only 1.1-2.2kW, and the energy consumption is much lower than other tin ore sorting equipment, which is suitable for long-term continuous operation. The equipment has a simple structure, few wearing parts and is easy to replace. Daily maintenance mainly includes checking the lubrication of transmission parts and the wear of the bed surface. The annual maintenance cost is only 2%-3% of the total equipment price, which can effectively control the production cost of tin ore processing. CATHAY is committed to creating higher economic benefits for customers.

7. Multiple specifications are available to meet different production capacity requirements

A variety of bed sizes are available (1.5m×3m, 2m×4m, etc.), and the single unit processing capacity covers 0.5-15 tons/hour, which can be flexibly selected according to the scale of tin mining and the capacity planning of the beneficiation plant. A single device occupies a moderate area, does not require a complex foundation during installation, can be quickly integrated into the existing tin ore sorting production line, and adapts to the installation requirements of different site conditions. CATHAY provides adaptation solutions for enterprises of different sizes.

8. CATHAY brand guarantee, perfect after-sales service for more peace of mind

CATHAY Yunxi shaker has been verified by the market for many years, and its technology is mature and stable. Each device undergoes strict material testing before leaving the factory to ensure that the tin ore sorting performance meets the standards. The professional after-sales team provides on-site installation and commissioning, operation training and fault repair services, and responds quickly to problems that arise during equipment operation, ensuring the continuous and stable operation of the tin ore sorting production line, so that customers can use it with more confidence.

Table parameters

|

名称

Name

|

床面尺寸(mm)

Bed surface size

|

给矿粒度

(mm)

Granularity

|

给矿量 (t/h) Orefeed

|

给矿浓度

(%)

Potency

|

功率 (kw) Power

|

冲程 (mm) Stroke

|

冲次(r/min) Jig frequency

|

重量 (kg) Weight

|

|

长度

|

传动端宽

|

精矿端宽

|

|

YX-1

|

4436

|

1825

|

1536

|

0.2-2

|

1-1.5

|

20-30

|

1.5

|

16-22

|

240-290

|

1012

|

|

YX-2

|

4436

|

1825

|

1536

|

0.037-0.5

|

0.6-1

|

15-25

|

1.5

|

10-20

|

300-320

|

1012

|

|

YX-3

|

4436

|

1825

|

1536

|

0.019-0.074

|

0.4-0.6

|

15-20

|

1.5

|

10-16

|

330-340

|

1012

|