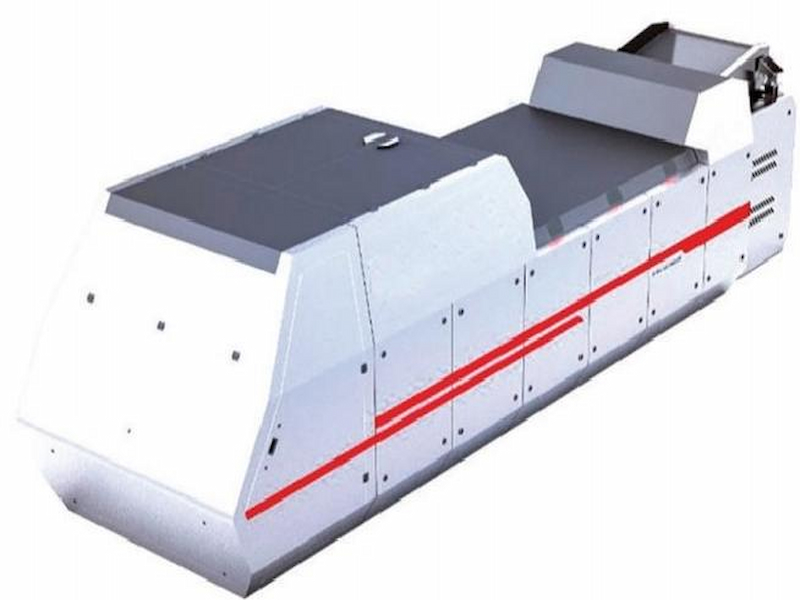

CATHAY intelligent ore dressing machine: AI empowers and opens a new era of intelligent ore dressing

I. AI-driven, reconstructing the entire ore dressing process

CATHAY intelligent ore dressing machine takes artificial intelligence algorithm as the core, integrates machine vision, sensor network and automatic control system, and realizes the full process intelligence from slurry detection, parameter adjustment to sorting execution. The deep learning model carried has been trained with tens of thousands of sets of ore dressing data, and can identify the mineral composition, particle size distribution and concentration changes in the slurry in real time, and optimize the sorting strategy autonomously. The response speed is more than 10 times faster than traditional manual adjustment, allowing the ore dressing process to be upgraded from "experience-driven" to "data-driven".

2. Multi-dimensional perception, accurate capture of mineral characteristics

Spectral detection system: built-in near-infrared spectral sensor, completes slurry composition analysis within 1 second, accurately identifies more than 20 minerals such as gold, silver, copper, tin, etc., and the component detection error is less than 2%.

Online particle size monitoring: The laser particle size analyzer monitors the distribution of 0.01-5mm mineral particles in real time, and the data is synchronously transmitted to the AI system to provide an accurate basis for the adjustment of sorting parameters.

Concentration and flow control: Through electromagnetic flowmeter and density sensor, the slurry concentration (adjustable from 10% to 50%) and flow stability are dynamically controlled to ensure the consistency of the sorting environment.

3. Adaptive sorting, efficient processing of multiple minerals

According to the characteristics of different minerals, the AI system can automatically switch the sorting mode:

① Metal ore mode: Achieve a recovery rate of more than 95% for gold and copper ores, and increase the concentrate grade by 15-25 percentage points;

② Non-metallic ore mode: The impurity removal rate of kaolin and quartz sand reaches 98%, meeting the requirements of high-end industrial raw materials;

③ Composite ore mode: When processing polymetallic symbiotic ores, the classification and sorting of multiple minerals are completed simultaneously to reduce the subsequent separation cost.

④ The equipment is compatible with the entire process of roughing, concentrating and scavenging, and the single unit processing capacity covers 5-50 tons/hour, which is suitable for the needs of ore dressing plants of different sizes.

4. Intelligent control, significant cost reduction and efficiency improvement

① Dynamic optimization of energy consumption: The AI system automatically adjusts the motor power according to the slurry load, reducing the comprehensive energy consumption by 20%-30%, and saving 10,000-50,000 kWh of electricity per year;

② Accurate reagent delivery: Linking the intelligent dosing device, adjusting the reagent dosage in real time according to the mineral composition, reducing reagent waste by more than 30%;

③ Labor cost saving: Unattended operation is achieved, and a single device can reduce 3-5 operators, saving 150,000-300,000 yuan in labor costs per year.

5.Industrial-grade design, stable and durable

① Anti-interference structure: Adopts electromagnetic shielding and dustproof and waterproof design (protection level IP65), which is suitable for the high dust and strong electromagnetic environment of the ore dressing plant;

② Wear-resistant core components: The sorting chamber is made of high-chromium cast iron, with a service life of more than 8,000 hours, which is 3 times longer than ordinary steel;

③ Redundant design: Key sensors and control systems are all equipped, and they are automatically switched in the event of a single point failure, shortening the downtime to less than 1 hour.

6. Digital twin, full life cycle management

Build a virtual model of the equipment through digital twin technology, map the operating status in real time, and support:

Remote monitoring: view production data, equipment parameters and energy consumption curves on mobile phones/computers;

Predictive maintenance: AI analyzes vibration, temperature and other data, and warns of potential failures 7 days in advance;

Production traceability: Automatically store sorting data for more than 3 years, support quality traceability and process optimization.

7.. CATHAY brand guarantee, intelligent service system

①Customized solution: According to the characteristics of mine resources, provide an integrated solution including equipment selection, algorithm training, and process design;

②Cloud support: The exclusive cloud platform continuously updates the AI algorithm, and the equipment can be upgraded online to maintain technological leadership;

③Professional operation and maintenance: 7×24 hours intelligent operation and maintenance center, response speed ≤30 minutes, and on-site service covers 90% of the country.

④CATHAY intelligent ore dressing machine has been applied in more than 300 ore dressing plants across the country, improving the ore dressing efficiency of customers by 35% and reducing the overall cost by 28% on average. From traditional mineral processing to intelligent upgrading, CATHAY redefines mineral processing standards with technological innovation, helping mining companies achieve efficient, green and sustainable development.

Table parameters

|

名称

Name

|

给矿粒度(mm) Granularity

|

处理量(t/h) Capacity

|

功率(kw)

Power

|

分选通道个数 Thoroughfare

|

外形尺寸(mm)

Outline dimensions

|

|

SIXS-1200

|

10-80

|

30-70

|

50

|

100

|

8250×2100×2100

|

|

SIXS-1400

|

10-80

|

50-90

|

60

|

120

|

8250×2300×2300

|

|

SIXS-1600

|

10-80

|

70-110

|

70

|

140

|

8250×2500×2300

|

|

SIXS-1800

|

10-80

|

70-130

|

80

|

160

|

8250×2500×2300

|

|

SIXS-X

|

10-100

|

70-240

|

130

|

450

|

5600×3000×2800

|