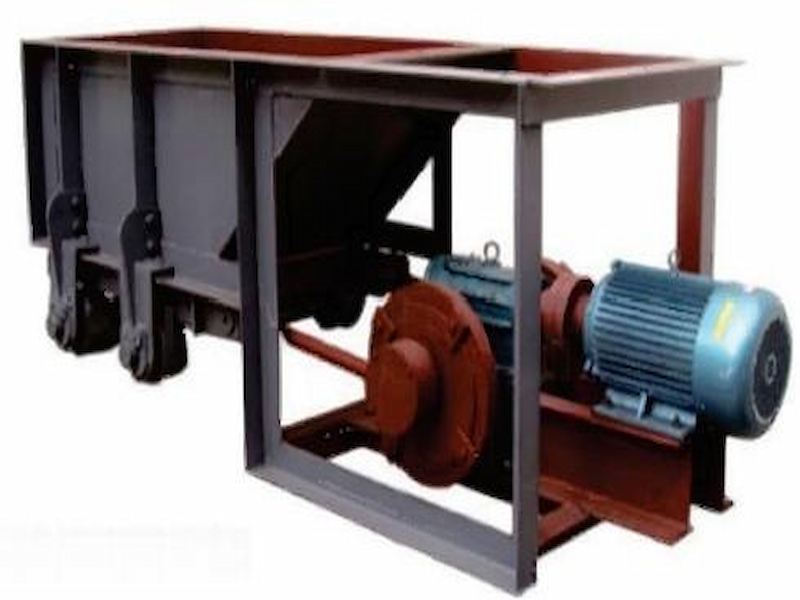

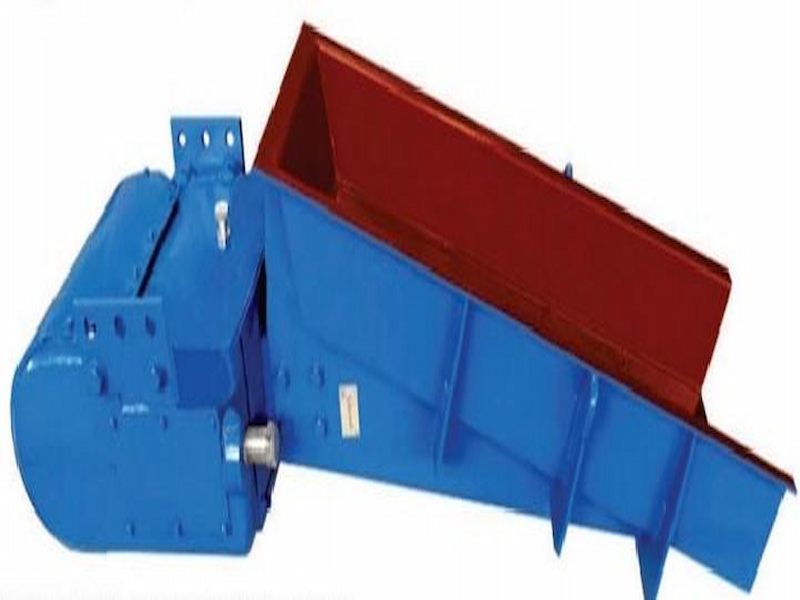

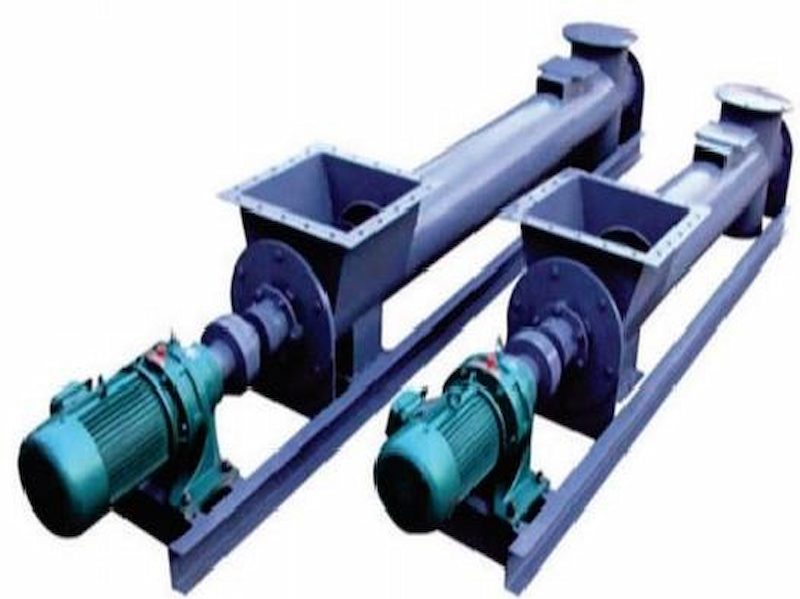

CATHAY chain feeder is a high-performance equipment designed for heavy material conveying. It uses high-strength alloy chain plates and heavy-duty roller chain transmission systems to stably convey large, high-temperature, and sharp materials. The maximum conveying capacity is 3000t/h, which is an ideal choice for mining, metallurgy, cement and other industries.

Core advantages

1. Super strong load-bearing capacity

- Heavy-duty chain plate: 16Mn alloy steel plate, thickness of 15-30mm, single plate load-bearing 2-5 tons

- Reinforced chain: Ø50-120mm large pitch roller chain, breaking force ≥800kN

- Heavy-duty design: The trough body adopts 20mm thick Q345 steel plate, and the overall rigidity is increased by 40%

2. Excellent wear resistance

- Triple protection: The surface of the chain plate can be treated with wear-resistant welding layer/ceramic patch/high chromium alloy**

- Long life: The life of key components is 3-5 years (2-3 times that of ordinary equipment)

- Easy to replace: modular chain plate design, single block replacement only takes 15 minutes

3. Stable and reliable operation

- Accurate speed regulation: hydraulic motor/frequency conversion motor is used, speed adjustment range is 0.01-0.3m/s

- Intelligent monitoring: equipped with chain tension monitoring and overload protection system

- Low maintenance: automatic lubrication system, maintenance interval ≥500 hours

4. Adaptation to special working conditions

- High temperature resistance: can convey hot materials ≤800℃ (with water cooling system)

- Anti-impact: buffer rollers are set at the bottom to resist the impact of falling materials

- Anti-deviation: patented guide device, offset ≤5mm

Technical parameters

| Parameter item | Specification range |

| Chain plate width | 800-2400mm |

| Conveying capacity | 100-3000t/h |

| Applicable particle size | ≤1500mm |

| Chain speed range | 0.01-0.3m/s |

| Motor power | 7.5-315kW |

| Tilt angle | 0-25° |

Industry solutions

✔ Metal mines: primary feeding of large ore (recommended plate width ≥1600mm)

✔ Steel plant: high-temperature material transportation of sintered ore and pelletized ore

✔ Cement industry: limestone, clinker and other abrasive material processing

✔ Coal industry: raw coal transportation (explosion-proof model optional)

Service support

- Customized design: provide anti-sticking/anti-corrosion/explosion-proof solutions according to material characteristics

- Fast delivery: conventional models are delivered within 15 days, and spare parts are shipped within 24 hours

- Lifetime service: provide equipment health monitoring and preventive maintenance** services

Table parameters

|

型号 Model

|

槽板宽度(mm) Slot width

|

头尾轮轴中心距(mm) Center distance

|

给料粒度(mm)

Feed particle size

|

处理能力(t/h) Capacity

|

功率(kw)

Power

|

|

BWO840

|

800

|

4000

|

≤500

|

70-100

|

7.5

|

|

BW0850

|

850

|

5000

|

≤500

|

100-160

|

11

|

|

BW1040

|

1000

|

4000

|

≤500

|

120-180

|

11

|

|

BW1060

|

1000

|

6000

|

≤500

|

150-200

|

15

|

|

BW1240

|

1200

|

4000

|

≤600

|

200-400

|

15

|

|

BW1260

|

1200

|

6000

|

≤600

|

250-500

|

18.5

|

|

BW1280

|

1200

|

8000

|

≤600

|

300-500

|

22

|

|

BW1490

|

1200

|

9000

|

≤600

|

400-600

|

37

|