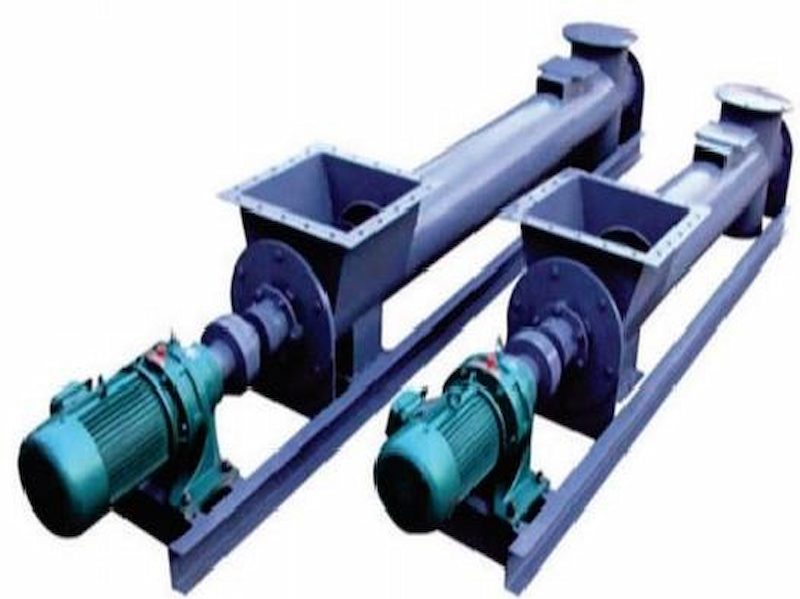

Product Overview:

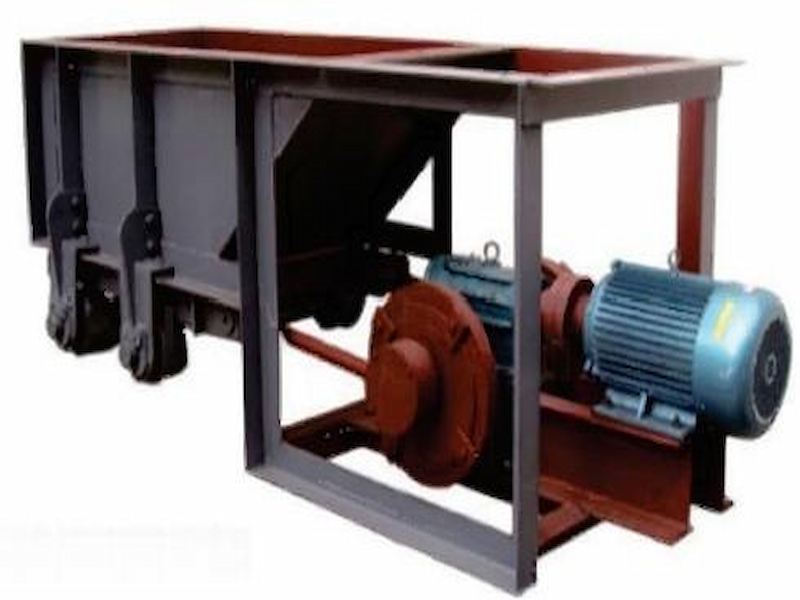

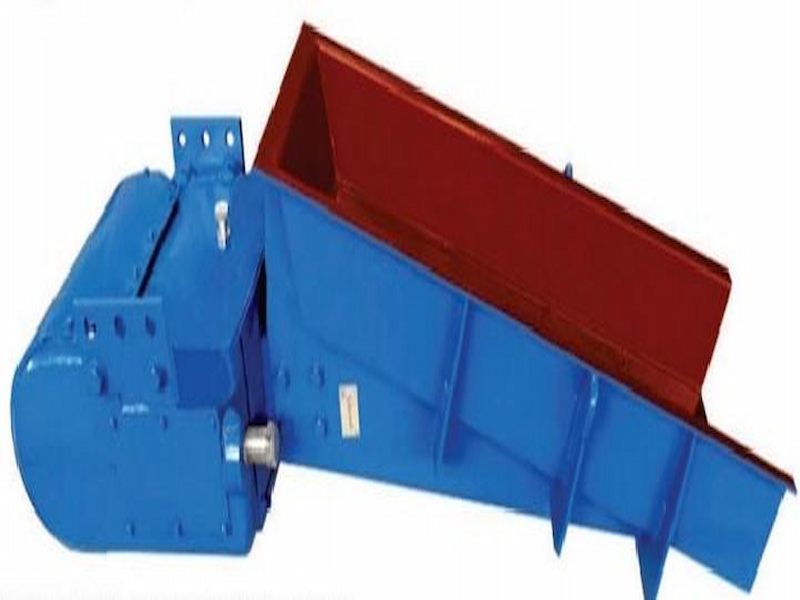

CATHAY spiral feeder is a continuous conveying equipment designed for powder, granular and small block materials. It adopts a precise spiral structure to achieve stable and efficient material transportation. It is widely used in chemical, food, building materials, environmental protection and other industries.

Core advantages:

✓ Efficient conveying

- Conveying capacity: 0.5-100m³/h adjustable

- Conveying distance: up to 30 meters

- Tilt angle: 0-90° adjustable to meet different working conditions

✓ Sealed and environmentally friendly

- Fully enclosed structure design to prevent dust spillage

- Food-grade materials that meet GMP standards are optional

- Operating noise <75 decibels

✓ Durable and reliable

- Spiral blades are made of wear-resistant alloy steel or 304/316 stainless steel

- Bearing life is more than 50,000 hours

- Simple maintenance and convenient replacement of accessories

✓ Intelligent control

- Frequency conversion speed regulation, precise and adjustable conveying volume

- Can be connected to the automatic control system

- Equipped with overload protection and alarm devices

Technical parameters:

- Pipe diameter range: Φ100-Φ600mm

- Material selection: carbon steel/stainless steel/food grade stainless steel

- Drive mode: motor direct connection/reducer drive

- Power range: 0.55-22kW

- Operating temperature: -20℃~120℃

Application scenarios:

✔ Chemical industry: powder raw material transportation

✔ Food processing: grain, additive distribution

✔ Building materials industry: cement, fly ash transportation

✔ Environmental protection engineering: sludge, waste treatment

✔ Pharmaceutical industry: precise feeding of raw materials

Customized service:

We provide a variety of configuration options:

- Shaftless spiral design (anti-winding)

- Explosion-proof motor configuration

- Heating/cooling jacket

- Special surface treatment (polishing, coating, etc.)

Quality assurance:

1. ISO9001 quality management system certification

2. Each equipment is strictly tested before leaving the factory

3. Provide 1-2 years warranty service

4. Professional technical team full support

|

Model

|

螺旋直径(mm) Corkscrew spin

|

螺距 (mm) Pitch

|

转速 (r/min) Speed

|

输送量

(m³/h)

Capacity

|

转速 (r/min) Speed

|

输送量 (m³/h)

Capacity

|

转速

(r/min)

Speed

|

输送量 (m³/h)

Capacity

|

转速

(r/min)

Speed

|

输送量

(m³/h)

Capacity

|

|

100

|

100

|

100

|

140

|

2.2

|

112

|

1.7

|

90

|

1.4

|

71

|

1.1

|

|

125

|

125

|

125

|

125

|

3.8

|

100

|

3

|

80

|

2.4

|

63

|

1.9

|

|

160

|

160

|

160

|

112

|

7.1

|

90

|

5.7

|

71

|

4.5

|

56

|

3.6

|

|

200

|

200

|

200

|

100

|

12.4

|

80

|

9.9

|

63

|

7.8

|

50

|

6.2

|

|

250

|

250

|

250

|

90

|

21.8

|

71

|

17.2

|

56

|

13.6

|

45

|

10.9

|

|

315

|

315

|

315

|

80

|

38.8

|

63

|

30.5

|

50

|

24.2

|

40

|

13.4

|

|

400

|

400

|

355

|

71

|

62.5

|

56

|

49.3

|

45

|

38.6

|

36

|

31.7

|

|

500

|

500

|

400

|

63

|

97.7

|

50

|

77.6

|

40

|

62

|

32

|

49.6

|

|

630

|

630

|

450

|

50

|

138.5

|

40

|

110.8

|

32

|

88.6

|

25

|

69.3

|

|

800

|

800

|

500

|

40

|

198.5

|

32

|

158.8

|

25

|

124.1

|

20

|

99.3

|