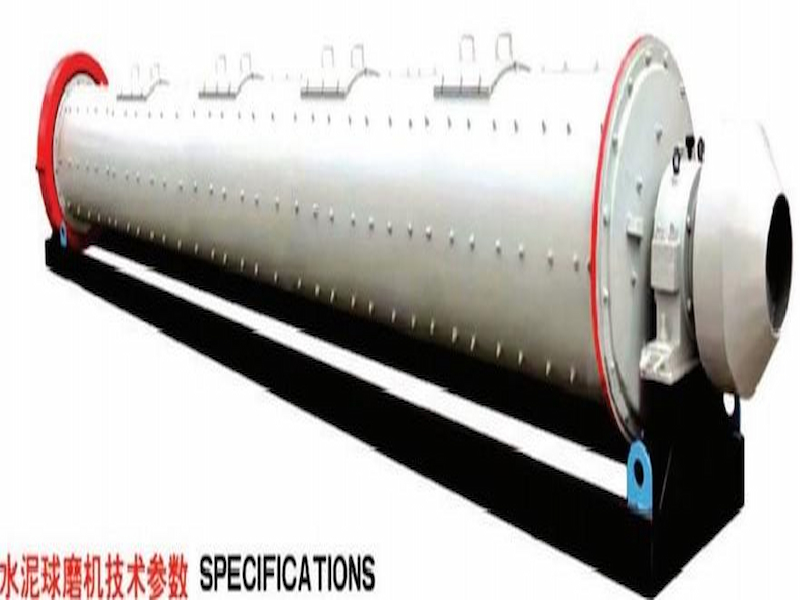

CATHAY Cement Ball Mill: Core Grinding Equipment for Cement Production

1. Focus on the cement field and grind cement clinker efficiently

CATHAY cement ball mill is specially designed for cement production process, and is especially good at fine grinding of cement clinker. When it is working, the cylinder rotates steadily at a specific speed. The steel balls loaded inside rotate with the cylinder under the action of centrifugal force and friction and are lifted to a certain height. Then they fall freely by gravity, which has a strong impact and continuous grinding on the cement clinker, and the block clinker is accurately refined into fine powder materials that meet the cement production standards, which effectively helps the preparation of cement finished products.

2. Adapt to various raw materials to meet the diverse needs of cement production

Not only does it have excellent grinding effect on cement clinker, but it can also flexibly handle a variety of raw materials in cement production, such as quicklime, gypsum, and mixed materials. By reasonably adjusting the steel ball grading, drum speed and grinding time, it can easily cope with raw materials of different hardness, humidity and particle size, ensuring that all kinds of materials can be ground to the ideal fineness, meeting the production needs of different cement varieties and strength grades, and widely applicable to the production of various cement products such as ordinary Portland cement, slag Portland cement, and composite Portland cement.

3. The discharge fineness is precisely controllable to ensure the stability of cement quality

Equipped with an advanced and precise fineness control system, the equipment operating parameters can be conveniently adjusted according to the strict requirements of actual cement production on the fineness of the finished product. Whether it is the control of medium fineness in ordinary cement production, or the strict standards of ultrafine particle size for special cement and high-performance cement, CATHAY cement ball mill can achieve it accurately. The stable discharge fineness makes the produced cement consistent in key performance indicators such as strength, setting time, and workability, which effectively guarantees the stability and reliability of cement product quality.

4. Sturdy and durable structure, stable and reliable operation

The cylinder is welded with high-strength and high-toughness high-quality steel, which can withstand long-term and high-frequency impact and friction between steel balls and materials, and has excellent anti-fatigue performance. The internal lining is made of wear-resistant rubber or high-manganese steel, which effectively reduces the wear of the cylinder and extends the service life of the equipment. The main bearing adopts a large-diameter double-row spherical roller bearing, which greatly reduces friction resistance and energy consumption, while ensuring the smooth operation of the equipment, reducing vibration and noise. The operating stability is much higher than similar products, effectively reducing the downtime caused by equipment failure and ensuring the continuous and efficient operation of the cement production line.

5. Flexible process, support for multiple production modes

It can be flexibly applied to both open-circuit grinding and closed-circuit grinding. In the open-circuit grinding system, the material passes through the mill at one time to complete the grinding operation, the process is simple, and the equipment investment cost is low; in the closed-circuit grinding system, it is used in conjunction with an efficient powder selector to select the finished product that meets the fineness requirements in time, and the coarse powder that does not meet the standard is returned to the mill for further grinding, which significantly improves the grinding efficiency, reduces the over-grinding phenomenon, and improves the cement output and quality. At the same time, the equipment is suitable for both dry grinding and wet grinding through specific designs to meet the process preferences and actual needs of different cement production companies.

6. Energy-saving and environmentally friendly design to help green cement production

The design fully incorporates the concept of energy conservation and environmental protection. Use high-efficiency energy-saving motors, optimize the transmission system, and reduce the power consumption during the operation of the equipment. Compared with traditional cement ball mills, the unit output energy consumption can be reduced by 10%-20%. The overall sealing performance of the equipment is good, and it is equipped with a professional pulse bag dust removal device, which can effectively capture the dust generated during the grinding process, ensuring that the dust emission concentration is far lower than the national environmental protection standard, reducing the pollution to the production environment and the surrounding atmosphere, and helping cement companies achieve green and sustainable development.

7. Brand professional guarantee, caring and worry-free after-sales

CATHAY, as a well-known brand that has been deeply involved in the field of cement equipment manufacturing for many years, relies on deep technical accumulation, rich production experience and strict quality control system to ensure that each cement ball mill has excellent performance and high quality. The professional after-sales team provides a full range of services from equipment installation and commissioning, operator training to regular maintenance and overhaul. We respond to customer needs 24/7 and promptly resolve various problems arising from equipment operation, allowing you to use CATHAY cement ball mill without worries and ensuring the stable and efficient operation of cement production.

Table parameters

|

规格 Model

|

转速 Speed

|

入料粒度(mm) Granularity

|

生产能力(t/h) Capacity

|

装球量(t) Ball load

|

主电机(kw)

Electric motor

|

主减速 Decelera 型号

|

器

tor

速比

|

重量(t) Weight

|

|

型号

|

功率

|

|

φ2.2×11

|

21

|

≤25

|

15~17

|

50

|

TR1512-8

|

570

|

Zd80

|

5.6

|

92

|

|

φ2.4×12

|

21

|

≤25

|

21~30

|

63

|

YR800-8/1180

|

800

|

MBY710

|

6.3

|

127

|

|

φ2.4×13

|

21

|

≤25

|

24~31

|

66

|

YR800-8/1180

|

800

|

MBY710

|

6.3

|

131

|

|

φ2.6×13

|

20

|

≤25

|

28~31

|

81

|

YR1000-8/1180

|

1000

|

JDX800

|

6.3

|

158

|

|

φ3.0×12

|

18

|

≤25

|

48~52

|

103

|

YR1250-8/1430

|

1250

|

JDX900

|

7.1

|

182

|

|

φ3.0×13

|

18

|

≤25

|

39~45

|

116

|

YR1400-8/1430

|

1400

|

JDX900

|

7.1

|

200

|

|

φ3.2×11

|

18

|

≤25

|

45~48

|

112

|

YR1600-8/1430

|

1400

|

JDX900

|

7.15

|

213

|

|

φ3.2×13

|

18

|

≤25

|

50~55

|

133

|

YR1600-8/1430

|

1600

|

JDX1000

|

7.15

|

237

|

|

φ3.4×11

|

18

|

≤25

|

45~55

|

120

|

YR1600-8/1430

|

1600

|

JDX1000

|

7.15

|

230

|

|

φ3.5×13

|

17

|

≤25

|

60~65

|

156

|

YR2000-8/1730

|

2000

|

TS130-A-F1

|

7.15

|

257

|