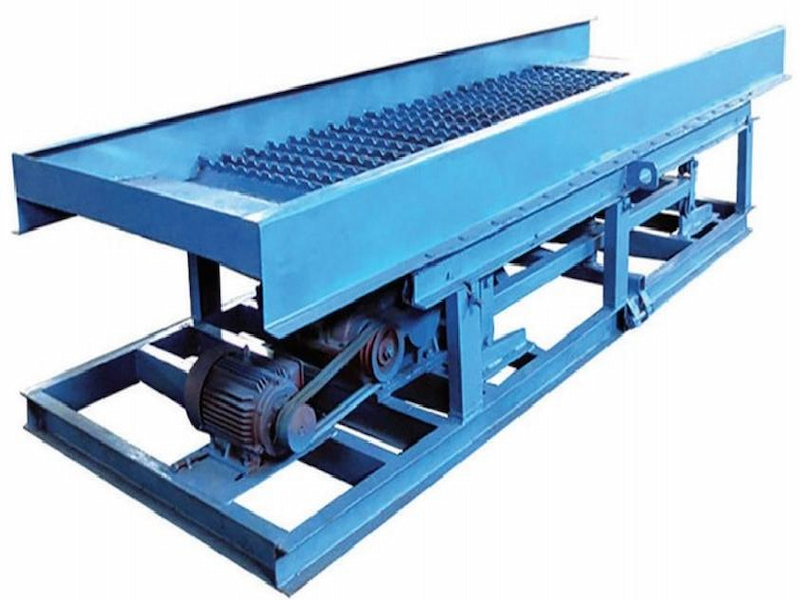

CATHAY agitation chute: agitation power for fine-grained mineral sorting

I. Agitation enhancement, reshaping fine-grained sorting efficiency

The core advantage of the CATHAY agitation chute is that it integrates the agitation device and the chute structure - the eccentric shaft drives the bottom plate to generate high-frequency vibration in the vertical direction (300-500 times/minute), and the inclination angle of the chute (3°-8°) enables the slurry to achieve efficient sorting under the dual effects of "gravity flow + agitation vibration". This composite movement can break the agglomeration state of fine-grained minerals and fully disperse the fine particles of 0.01-0.1mm, which is 20%-30% higher than the fine particle recovery rate of traditional chutes, and is especially suitable for the sorting of minerals with small density differences.

2. Accurate stratification, significantly improved recovery rate of fine-particle minerals

Under the synergistic effect of agitation vibration and water flow, the ore particles are quickly stratified according to density differences: high-density useful minerals (such as placer gold, fine-particle tin, iron ore concentrate, etc.) are quickly settled to the enrichment area at the bottom of the chute due to the vibration and collected by the end concentrate tank; low-density gangue minerals flow along the surface of the chute with the water flow and are discharged from the tailings outlet. The recovery rate of placer gold can reach more than 90%, and the grade of concentrate is 15-20 times higher than that of the original ore, effectively reducing the loss of fine-particle useful minerals and improving resource utilization.

3. Adaptable to a variety of fine-particle minerals, with a wide range of application scenarios

Designed for the separation of fine-particle and fine-particle minerals, it can efficiently process placer gold, placer gold, fine-particle tin ore, iron ore, manganese ore, etc., and can also perform secondary recovery of flotation tailings and re-selection of minerals. It performs outstandingly in small-scale sand mining, river gold panning, mine tailings recovery and other scenarios. It is especially suitable for field operations or production environments with limited sites. A single device can complete the roughing-selection process and reduce the intermediate transfer links.

4. Compact structure, durable and reliable agitation system

The chute body is molded with fiberglass material, with a smooth and wear-resistant surface and excellent corrosion resistance. It can withstand long-term erosion of high-concentration slurry and has a service life of 5-7 years. The eccentric shaft and bearing of the agitator are made of high-strength alloy materials, and with a sealed and dustproof design, it can still operate stably under humid and dusty conditions, with a failure rate of less than 5%, reducing the maintenance frequency.

5. Easy operation, flexible and intuitive parameter adjustment

Equipped with a knob-type adjustment panel, it can easily control the agitation frequency, chute inclination and feed rate, and quickly optimize the sorting parameters according to the characteristics of different types of ores. The operating status of the equipment is intuitively visible. The operator can judge the sorting effect by observing the flow state of the slurry and the distribution of the concentrate belt. It can be operated independently after 30 minutes of training, which reduces the threshold for production employment.

6. Low consumption and energy saving, controllable operating costs

The drive motor adopts the YE2 high-efficiency energy-saving model with a power of only 0.75-1.5kW. When running at full load, it can save more than 2,000 degrees of electricity per year. The equipment has a simple structure and a small footprint (about 1.5-3㎡ for a single unit). It does not require a complex installation foundation and is suitable for temporary outdoor work sites. There are few wearing parts and low procurement costs. Daily maintenance only requires regular inspection of the lubrication of the vibrating parts, and the annual maintenance cost is controlled within 2% of the total equipment price.

7. Modular design, production capacity is configured on demand

It provides a variety of specifications such as single slot, double slot, and four slots. The processing capacity of a single unit covers 0.2-5 tons/hour, which can be flexibly combined according to the production scale. Continuous operation can be achieved when multiple slots are connected in parallel, and the processing capacity is linearly superimposed. The equipment is light in weight (about 100-300kg for a single slot), which is easy to carry and move, meeting the flexible production needs of "mining and selecting as needed" in small mines.

8. CATHAY brand guarantee, worry-free full-cycle service

Each agitator chute undergoes a 48-hour no-load vibration test and a 72-hour material-carrying operation test to ensure that the vibration parameters are stable and the sorting effect meets the standards. We provide services such as on-site installation and commissioning, operation skills training, spare parts kits, etc., 7×24-hour technical hotline response to fault repair, and promise to repair on-site within 24 hours in county-level areas, so that customers can also get reliable support in field operations or small-scale production.

Table parameters

|

型号 Model

|

外形尺寸(mm)

Size

|

处理量 (m³/h) Orefeed

|

给矿粒度

(mm)

Granularity

|

给矿浓度

(%)

Potency

|

耗水量

(m³/h)

Water

|

功率 (kw) Power

|

鼓动频率 (次/min) Frequency

|

安装倾角 Angle

|

排矿周期(h) Cycle

|

重量(kg) Weight

|

|

FGS-12

|

3200×1200×730

|

20-25

|

<20

|

30

|

40-50

|

1.1

|

28-30

|

6°-7°

|

4

|

750

|

|

FGS-15

|

4000x1500×730

|

30-35

|

<20

|

30

|

60-80

|

2.2

|

28-30

|

6°-7°

|

4

|

1100

|