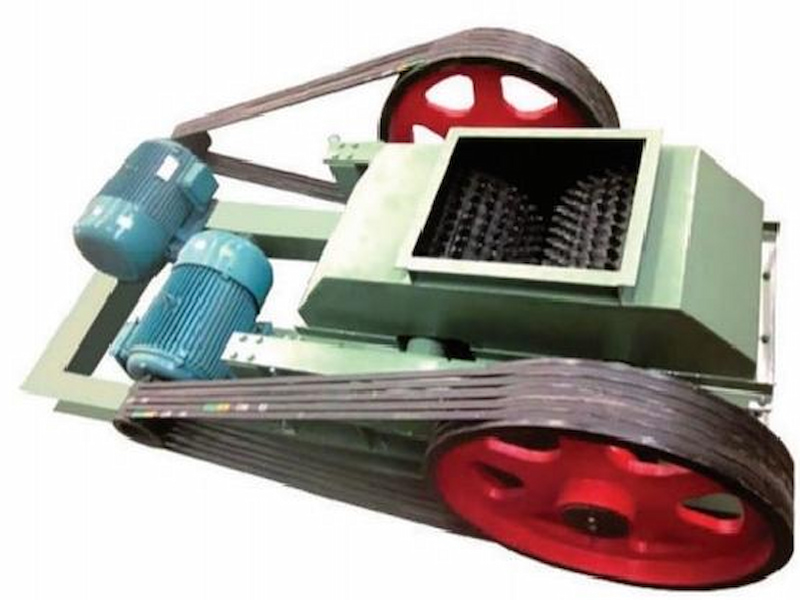

CATHAY tooth roller crusher

Core advantages

1. Strong tooth roller bite: The double rollers with special tooth shape design can achieve material crushing through high-strength bite, which has significant crushing effect on sticky and tough materials and avoids slippage and blockage.

2. Uniform crushing particle size: The gap between the tooth rollers can be accurately adjusted to ensure stable discharge particle size and reasonable finished product grading to meet different production requirements.

3. Wear resistance and damage resistance: The tooth rollers are made of high-strength alloy materials and have undergone special heat treatment processes, which have strong wear resistance and greatly extend their service life.

4. Energy saving and high efficiency: The transmission system is optimized in design, with low power loss, high crushing efficiency, and lower unit energy consumption than traditional models.

Applicable scenarios

It is widely used in the medium crushing of materials such as coal, coke, shale, limestone, etc., especially suitable for coal preparation plants, coal chemical industry, building materials and other fields with high requirements for material crushing effect.

Brand guarantee

CATHAY tooth roller crusher, integrating advanced tooth shape design and reliable performance, provides customers with stable crushing solutions, and the after-sales team responds promptly to ensure smooth production.

Table parameters

Table parameters

|

规格型号 Model

|

辊子直径

(mm)

Diameter

|

辊子长度 (mm)

Length

|

进料粒度 (mm)

Size

|

排料粒度(mm)

Size

|

产量(t/h) Capacity

|

功率(kw)

Power

|

重量(kg) Weight

|

外形尺寸(mm)

Dimension

|

|

2PGC450×500

|

450

|

500

|

200-500

|

25-125

|

30-60

|

5.5×2

|

3800

|

2260×2200×766

|

|

2PGC600×500

|

600

|

400

|

200-500

|

25-125

|

40-60

|

7.5×2

|

4500

|

2450×1800×950

|

|

2PGC600×750

|

600

|

750

|

300-600

|

30-150

|

60-100

|

11×2

|

7200

|

2780×3065×1310

|

|

2PGC600×900

|

600

|

900

|

300-600

|

30-150

|

80-120

|

18.5×2

|

7800

|

4500×1900×1350

|

|

2PGC800×1050

|

800

|

1050

|

500-800

|

30-150

|

100-160

|

22×2

|

12600

|

2550×2050×1100

|

|

2PGC900×900

|

900

|

900

|

600-900

|

30-200

|

150-200

|

22×2

|

13500

|

2780×4100×1550

|

|

2PGC1015×760

|

1015

|

760

|

700-950

|

30-200

|

150-200

|

45×2

|

18800

|

7800×3200×1980

|

|

2PGC1200×1500

|

1200

|

1500

|

800-1050

|

30-200

|

200-300

|

55×2

|

52000

|

8010×4500×2050

|