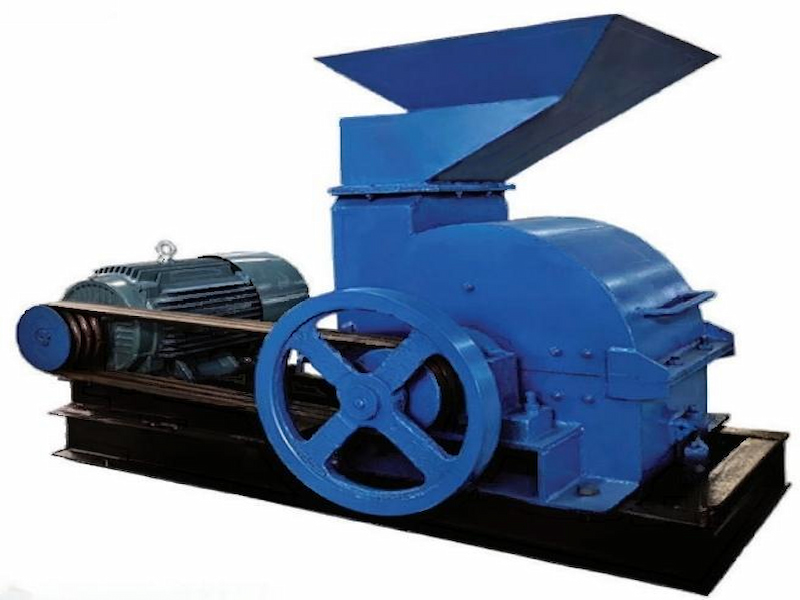

CATHAY sand blasting machine

Efficient sand making, outstanding production capacity

Adopting the impact crushing principle, the high-speed rotating impeller accelerates the material to be thrown out, collides and grinds with the impact plate and the material to achieve rapid sand making. The equipment has strong processing capacity and can produce tens to hundreds of tons of sand per hour, which can meet the large-scale production needs of large-scale construction projects, sand and gravel plants, and greatly improve the efficiency of sand making.

The finished product has high-quality particle shape and reasonable grading

The unique crushing chamber design and impeller structure allow the material to be subjected to uniform force during the crushing process. The finished sand particle shape is cubic, round and full, without too many needle-like particles. The equipped screening device can accurately control the size of the sand particles, and the grading meets the standards for construction sand, and can be directly used in scenes such as concrete mixing and road paving.

Wear-resistant and durable

Core components such as impellers and impact plates are made of high-chromium alloy. After special heat treatment process, they have high hardness and strong wear resistance and can withstand continuous impact and friction of materials. The overall structure of the equipment is stable and the sealing performance is good, which reduces the entry of dust into internal parts, prolongs the service life, and reduces the frequency of replacement of wearing parts.

Easy to operate, intelligent and controllable

Equipped with an intelligent control system, the impeller speed, feed amount and other parameters can be adjusted through the touch screen to accurately control the particle size of the finished sand. The equipment operation status is displayed in real time, and an alarm is automatically given when a fault occurs, prompting the cause, which is convenient for timely investigation. The one-button start-stop design simplifies the operation process, and novices can get started after simple training.

Widely applicable, strong material compatibility

It can handle a variety of materials such as river pebbles, granite, basalt, limestone, and construction waste. Whether it is hard rock sand making or waste resource utilization, it can be completed efficiently. It is widely used in construction materials, road construction, water conservancy projects, concrete prefabricated parts and other industries to meet the sand needs of different scenarios.

Energy-saving and environmental protection, green production

Use low-noise motors with sound insulation devices to reduce noise pollution during operation. The closed operation design is combined with an efficient dust removal system to reduce dust emissions and meet environmental protection requirements. The equipment has low energy consumption, and the unit sand making energy consumption is lower than that of traditional models, helping enterprises achieve green and low-carbon production.

Brand guarantee, considerate after-sales service

CATHAY sand blasting machine integrates advanced sand making technology and strict manufacturing standards, and its quality is guaranteed. The professional after-sales team provides on-site installation and commissioning, technical guidance, regular maintenance and other services to promptly solve problems in equipment operation, so that customers can produce without worries.

Table parameters

Table parameters

|

型号 Model

|

处理能力(t/h) Capacity

|

给料粒度(mm)

Feed grain size

|

排料粒度(mm) Grain size

|

电机(kw)

Motor

|

柴油机(匹)

Diesel engine

|

重量(kg) Weight

|

|

250×500

|

1-2

|

≤50

|

≥1.5

|

7.5-11

|

20

|

300

|

|

300×500

|

3-6

|

≤50

|

≥1.5

|

11-15

|

24

|

350

|

|

400×500

|

5-10

|

≤50

|

≥1.5

|

11-22

|

30

|

560

|

|

400×600

|

8-15

|

≤50

|

≥1.5

|

15-30

|

45

|

780

|