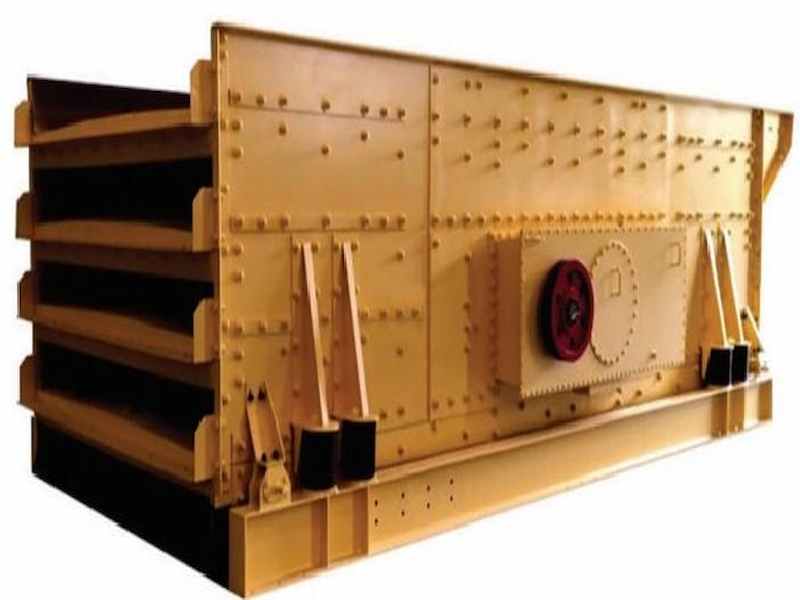

CATHAY horizontal vibrating screen adopts the principle of low-angle horizontal vibration (0-5° inclination) and is a professional screening equipment designed for fine classification and difficult-to-screen materials. It is suitable for high-demand industries such as chemical, food, and medicine, with a processing capacity of 0.5-50t/h and a screening accuracy of up to 0.038mm (400 mesh), achieving nearly horizontal and efficient material flow.

Core advantages

1. Precision screening technology

- Micro-horizontal vibration: amplitude 1-3mm, to avoid material crushing (especially suitable for crystal/brittle materials)

- Multi-layer fine grading: 1-5 layers of screen configuration, while producing 4-6 specifications of finished products

- Zero clogging design: bouncing ball/ultrasonic screen cleaning system optional

2. Sanitary structural design

- Optional materials: 304/316L stainless steel (Ra≤0.8μm mirror polishing)

- No dead angle structure: arc transition + quick-open clamp (cleaning time <15 minutes**)

- GMP compliance: FDA/CE certified (special model for medicine and food)

3. Intelligent control system

- Frequency conversion adjustment: vibration frequency 500-3000 times/minute stepless speed change

- Internet of Things module: real-time monitoring of screen damage, output and energy consumption

- One-click production change: store 20 sets of process parameters

4. Industry customized solutions

- Chemical grade: explosion-proof motor + gas seal (for handling flammable and explosive powders)

- Medical grade: all stainless steel + IP65 protection (for sterile environments)

- Mining version: thickened wear-resistant screen plate (lifespan **≥12 months**)

Technical parameters

| Parameters | Standard specifications | Customization range |

| Screen surface size | 800×2500mm | 400×1200mm~2000×6000mm |

| Screening accuracy | 0.074-10mm | 0.038-25mm |

| Processing capacity | 0.5-20t/h (single layer) | Up to 50t/h |

| Power | 0.75-7.5kW | Explosion-proof motor optional |

| Noise | ≤70dB | Silent type ≤65dB |

Typical applications:

✔ Mining and metallurgy:

- Quartz sand 30-100 mesh particle size control

- Metal powder anti-oxidation screening (nitrogen protection option)

Service support

- Verification test machine: provide 20kg material free test screening

- Fast delivery: standard model shipped within 7 days

- Global certification: CE, FDA, ATEX (explosion-proof)

Table parameters

|

型号 Model

|

功率(kw)

Power

|

转速(r/min) Speed

|

筛层数 Storey

|

筛面规格(mm) Screen size

|

给料尺寸(mm) Feed size

|

处理量(t/h) Capacity

|

运动轨迹

Trajectory

|

可选件 Option

|

|

SHS2060

|

37

|

730-875

|

2

|

1950×6000

|

250

|

300-650

|

椭圆

|

淋水除尘管

橡胶弹簧

基础机架

金属编织筛网

底部张紧的底层筛

楔型夹装置

粗筛配置

防堵球筛层

|

|

SHS2060

|

37

|

3

|

1950×6000

|

|

SHS2470

|

45

|

2

|

2400×7000

|

350-750

|

|

SHS2470

|

45

|

3

|

2400×7000

|

|

SHS2775

|

55

|

2

|

2700×7500

|

450-950

|

|

SHS2775

|

55

|

3

|

2700×7500

|