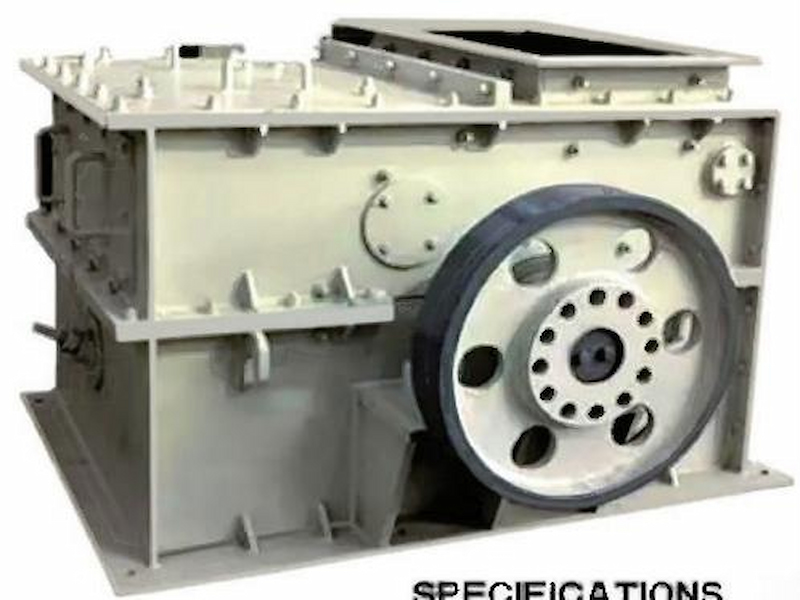

CATHAY hammer crusher, the most efficient choice for material crushing

1. Powerful crushing performance

CATHAY hammer crusher is equipped with a high-speed rotating rotor, on which multiple ring hammers are tightly installed. When the material enters the crusher from the upper feed port, it is immediately subjected to the violent impact of the high-speed rotating hammer. The powerful impact force of the hammer instantly crushes the material, and then the material is further crushed and refined in the crushing chamber due to mutual collision, extrusion and grinding. This all-round crushing method enables it to have extremely high crushing efficiency and large processing capacity for brittle, medium-hard and low-water materials such as coal, coal gangue, coke, slag, loose limestone, etc., which can fully meet the needs of large-scale production.

2. Accurate particle size control

It has a convenient and accurate particle size adjustment system, which can flexibly adjust the grate plate gap according to the strict requirements of actual production on the particle size of the discharge. Whether it is the specific particle size required for the production of building aggregates, or the stringent standards for the particle size of raw materials in the chemical, power and other industries, CATHAY hammer crushers can accurately achieve them, ensuring the output of high-quality finished materials with uniform particle size and regular shape, greatly meeting the needs of multiple production scenarios.

3. Compact and durable design

The overall structural design is compact and reasonable, with a small footprint, and can be easily placed in a limited production site, effectively saving space resources. Crusher key components such as hammers and grate plates are carefully manufactured with high-hardness, high-wear-resistant high-quality materials. In the face of long-term, high-frequency impact and friction of materials, it can still maintain a good working state and significantly extend the service life of the equipment. At the same time, the overall structure of the equipment is stable and the operation stability is extremely strong, which greatly reduces the production interruption caused by equipment failure.

4. Environmentally friendly and low-consumption operation

In terms of environmental protection, the crusher is equipped with an efficient sealing device and dust removal system, which can greatly reduce dust spillage, reduce noise pollution, and create a clean and quiet production environment, which is in line with the current green production concept. The transmission system has been optimized and designed, and the power transmission is efficient and stable, which effectively reduces energy loss and realizes energy-saving operation. It reduces unit energy consumption while increasing production capacity, saving production costs for enterprises.

5. Wide range of industry adaptation

In the power industry, it can efficiently crush coal and provide high-quality fuel for thermal power generation; in the field of building materials, it is used to process raw materials such as limestone to provide materials of suitable particle size for cement and brick production; in the metallurgical industry, it is used to perform medium and fine crushing of ore. It is widely used in many industries such as mining, building materials, electricity, metallurgy, and chemical industry, and has become the core equipment in the material crushing link.

6. Brand strength support

As a well-known brand in the field of mining machinery, CATHAY strictly controls every production process of the hammer crusher with its profound technical accumulation and rich manufacturing experience to ensure excellent product performance and reliable quality. The professional after-sales team is on call at any time to provide customers with timely and professional technical support and all-round after-sales service, so that you can use it with more peace of mind.

Table parameters

|

型号 Model

|

进料粒度(mm)

Feed grain size

|

出料粒度(mm) Grain size

|

产量(t/h) Capacity

|

转速(r/min) Rotor speed

|

功率(kw)

Power

|

重量(t) Weight

|

外型尺寸(mm) Outer size

|

|

PCHO402

|

=<200

|

=<30

|

8-12

|

960

|

5.5

|

0.8

|

810×890×560

|

|

PCHO404

|

=<200

|

=<30

|

16-25

|

970

|

11

|

1.05

|

980×890×570

|

|

PCHO604

|

=<200

|

=<30

|

22-33

|

970

|

15

|

1.43

|

1050×1270×800

|

|

PCHO606

|

=<200

|

=<30

|

30-60

|

980

|

30

|

1.77

|

1350×1270×1080

|

|

PCHO808

|

=<200

|

=<30

|

70-105

|

740

|

45

|

3.6

|

1750×1620×1080

|

|

PCH1010

|

=<300

|

=<30

|

160-200

|

740

|

90

|

6.1

|

2100×2000×1340

|

|

PCH1016

|

=<300

|

=<30

|

300-350

|

740

|

155

|

9.2

|

2700×2000×1350

|

|

PCH1216

|

=<350

|

=<30

|

620-800

|

740

|

355

|

15

|

4965×2500x1600

|

|

PCH1322

|

=<400

|

=<30

|

800

|

595

|

400

|

24.9

|

6333×3295×2505

|